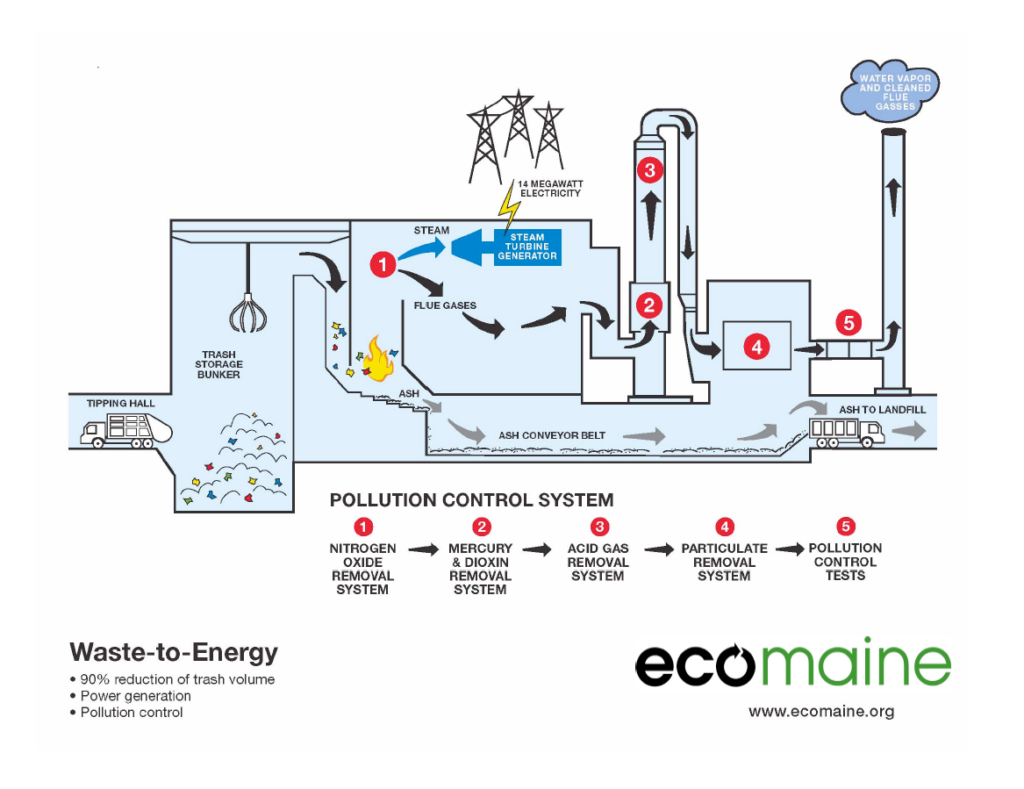

Our waste-to-energy (WTE) plant receives trash identified as un-recyclable and converts it at 2,000 degrees Fahrenheit to energy in the form of electricity. The ecomaine WTE plant processes about 175,000 tons of trash a year and, from that process, generates enough steam to create about 100,000 megawatt-hours of electricity annually. That’s enough electricity to power our WTE and recycling facilities, our company’s electric vehicles, plus about 15,000 homes for a year!

Converting the trash to energy also benefits the communities we serve by reducing its volume by 90 percent, leaving only inert ash to be stored at the landfill site. (There are also statewide economic benefits from WTE plants; click here to read the results of a Maine study).

By reducing the volume of trash by 90%, controlling pollution, and generating electricity, waste-to-energy clearly has many benefits. These and more are outlined in a 2021 study by Dr. Marco Castaldi, The Scientific Truth about Waste to Energy Facilities and Quantifiable Benefits They Provide. (Sneak Peek: did you know that areas in the U.S. with waste-to-energy have higher recycling rates than those without?)

ecomaine‘s state-of-the-art WTE plant opened in 1988 and operates around the clock, every day of the year, with the exception of an annual two-week shut down for each boiler to conduct planned maintenance. The building was designed with negative pressure to trap any odors inside and to re-circulate that air for boiler combustion.